NE500-Плиточная цепная бункер-лифт

Основные технические параметры:

Двухрядная цепь

Пропускная способность: 470 м³/ч

Скорость цепи: 0.5 м/с

Частота вращения главного вала: 7.1 об/мин

Размер ковша: 260.9 л, ширина ковша 700 мм, расстояние между ковшами 700 мм

Тип цепи: пластинчатая цепь с втуленными роликами и шлицовыми шариками, шаг цепи 350 мм, внутренние и внешние пластины цепи 40Cr, шпилька 20CrMnMo, втулка 20CrMo, ролик 20CrMo.

Максимальный размер материала: 240 мм - 10%, 190 мм - 25%, 145мм - 50%, 120мм - 75%, 100 мм - 100%.

this type of elevator is commonly found in:

- Mining Industry (iron ore, copper ore, etc.)

- Quarry Industry (crushed stone, gravel handling)

- Metallurgy Industry (slag, ore lifting)

- Construction Materials Industry (heavy aggregates, cement raw materials)

Basic Info.

Model NO.

| NE 500 |

Color

|

Multi Color

|

Condition

|

New

|

Bucket Width

|

700 mm

|

Bucket Material

|

Q235B,SUS304,16Mn |

No. of Discharge Port

|

Single or Muti Discharge Port

|

Voltage

|

220~550V

|

Motor Power

|

7.5-45kw

|

Driven Type

|

Electric Motor

|

Transport Package

|

Standard Export Package

|

Material

|

Stainless Steel

|

Application

|

Chemical Industry, Grain Transport

|

Product Name

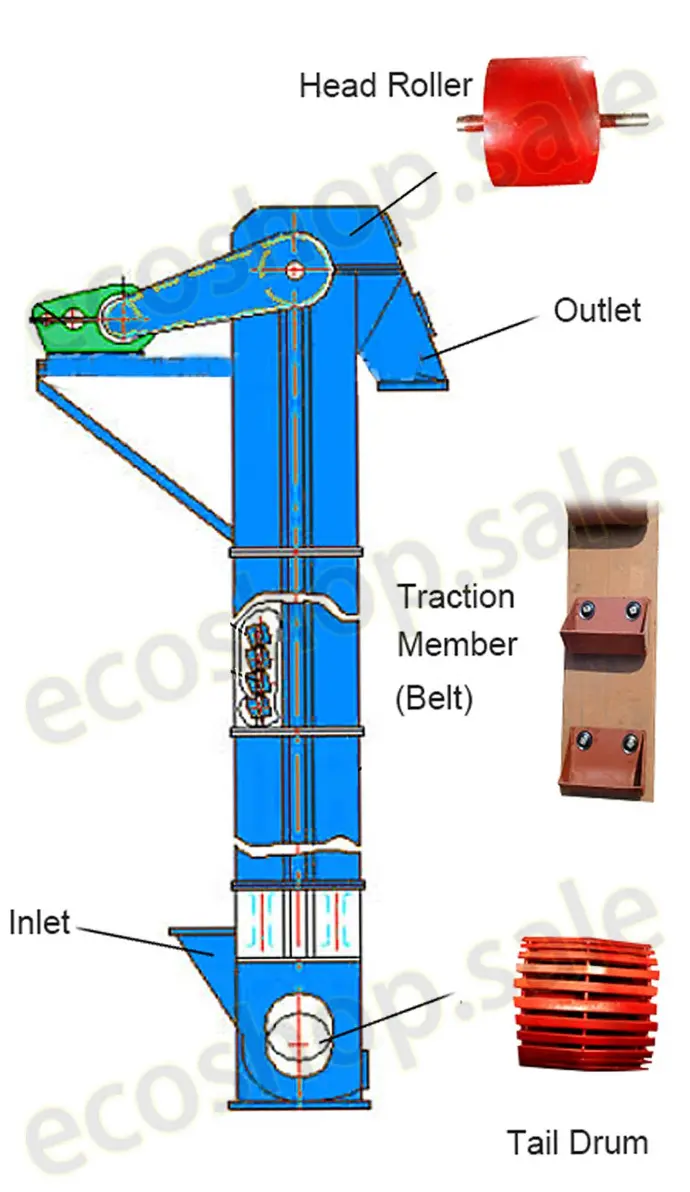

| Wire rope core belt bucket elevator |

Bucket Volume

| 260.9 L |

Body Material

|

Mild Steel, Stainless Steel 304 or Other

|

Speed

|

Adjustable or Fixed

|

Good Sealing

|

Prevent Environmental Pollution

|

Specification

|

customized

|

Production Capacity

|

200 Sets Per Months

|

Trademark | Ecoshop |

HS Code | 8428391000 |

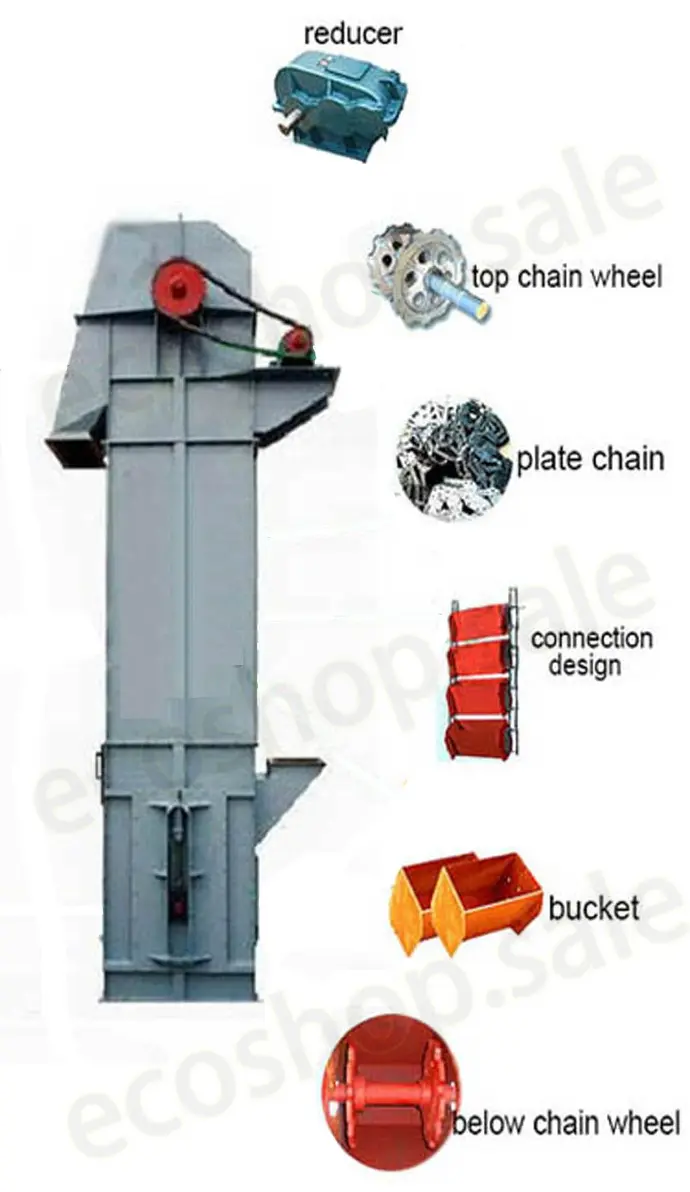

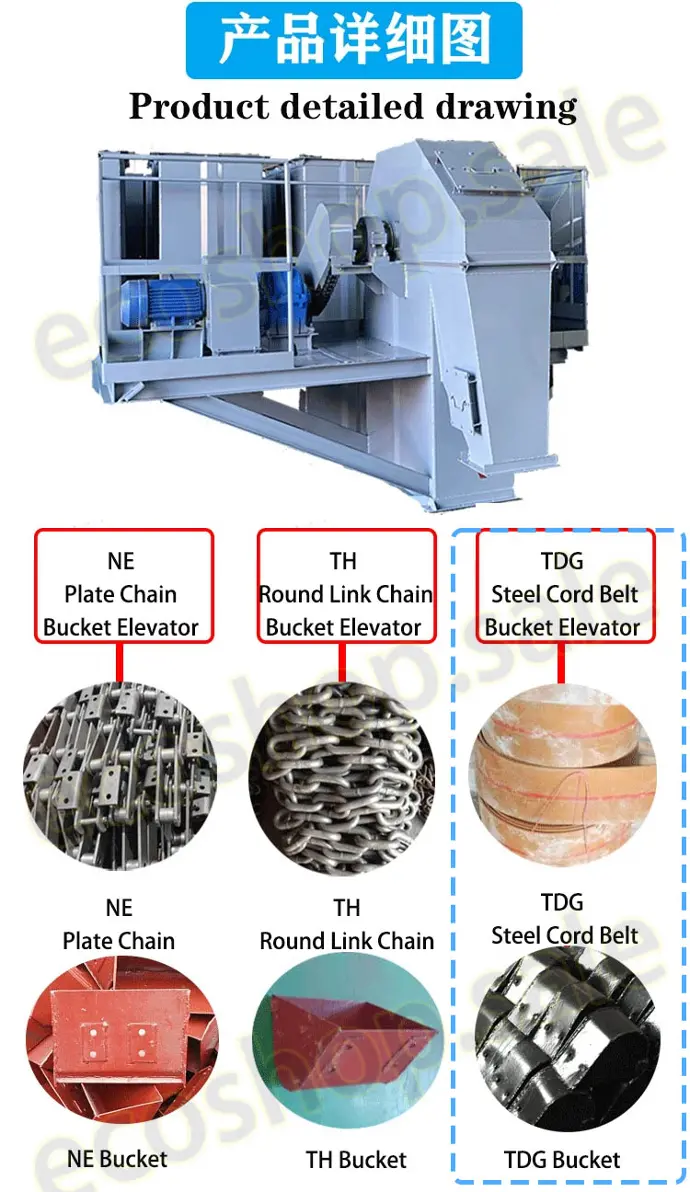

Plate chain bucket elevator

The NE series plate chain bucket elevator stands out in the field of material handling with its distinctive technical advantages. Equipped with high-strength and wear-resistant plate chain design, this equipment not only enhances the overall structural stability but also significantly boosts material conveying efficiency and stability. Its unique sprocket drive system minimizes friction and wear during operation, achieving low-noise and energy-efficient eco-friendly performance. Furthermore, the NE series bucket elevator offers flexible adjustment capabilities, enabling precise adjustments based on the properties of different materials and conveying requirements, ensuring efficient and accurate vertical material transportation. It is widely applied across various industries, including chemicals, building materials, and food processing.

There are two types of plate chain bucket elevators: the conventional NE series and the high-speed NSE series. The main difference lies in their application: the NE series is designed for conveying bulk materials with larger particle sizes, while the NSE series, due to its higher speed, is more suitable for materials with smaller particle sizes. The specific selection between the two depends on the particle size compatibility conditions of each model. When the material particle size is small and meets the criteria of the NSE series, choosing the NSE series can help reduce the size of the elevator, leading to lower design costs.

Differences between bucket elevators

TDG Series

Steel Cord Belt Bucket Elevator--The traction part is steel cord core conveyor belt, adopting centrifugal or mixing method of discharging, which is suitable for conveying non-abrasive and semi-abrasive materials in the form of powder, granule and small block with the accumulation density less than 1.5t/m3. When ordinary rubber belt is used, the material temperature should not exceed 60℃; when heat-resistant rubber belt is used, the maximum material temperature should not exceed 150℃.

this type of elevator is commonly found in:

- Food Processing Industry (such as grains, sugar, coffee beans)

- Chemical Industry (non-corrosive powders, plastic granules)

- Plastics Manufacturing (raw material handling)

- Light Manufacturing (handling of light raw materials and finished products)

TH Series

Round Chain Bucket Elevator--The traction parts are high-strength round ring chain, adopting mixed type or gravity type discharging, suitable for conveying non-abrasive and semi-abrasive materials of powder, granule and small block with the bulk density less than 1.5 t/m3, and the temperature of the materials should not be more than 250°C.

this type of elevator is commonly found in:

- Metallurgy Industry (e.g., sintering ore, hot ores processing)

- Cement and Building Materials Industry (clinker, limestone, fly ash)

- Mining Industry (various mineral processing)

- Power Industry (coal handling in power plants)

NE Series

Plate Chain Bucket Elevator--The traction part is plate sleeve roller chain, the running speed of the hopper is 0.5 m/s, and it adopts gravity type discharging method, which is suitable for conveying the medium and large lumpy abrasive materials with the stacking density of less than 2.2t/m3, and the temperature of the materials should not be more than 250°C.

this type of elevator is commonly found in:

- Mining Industry (iron ore, copper ore, etc.)

- Quarry Industry (crushed stone, gravel handling)

- Metallurgy Industry (slag, ore lifting)

- Construction Materials Industry (heavy aggregates, cement raw materials)

Comparison

In summary, bucket elevators utilizing steel cord belts excel in handling light, non-abrasive materials at lower temperatures, making them ideal for food and chemical industries. Ring chain bucket elevators, capable of withstanding higher temperatures, are suited for transporting moderately dense materials in sectors like metallurgy and construction. Plate bushed roller chain bucket elevators, designed for heavier, abrasive materials at elevated temperatures, find their application predominantly in mining and heavy manufacturing. Each type is optimized for specific material characteristics and industry demands, ensuring efficient vertical transportation in diverse industrial settings.